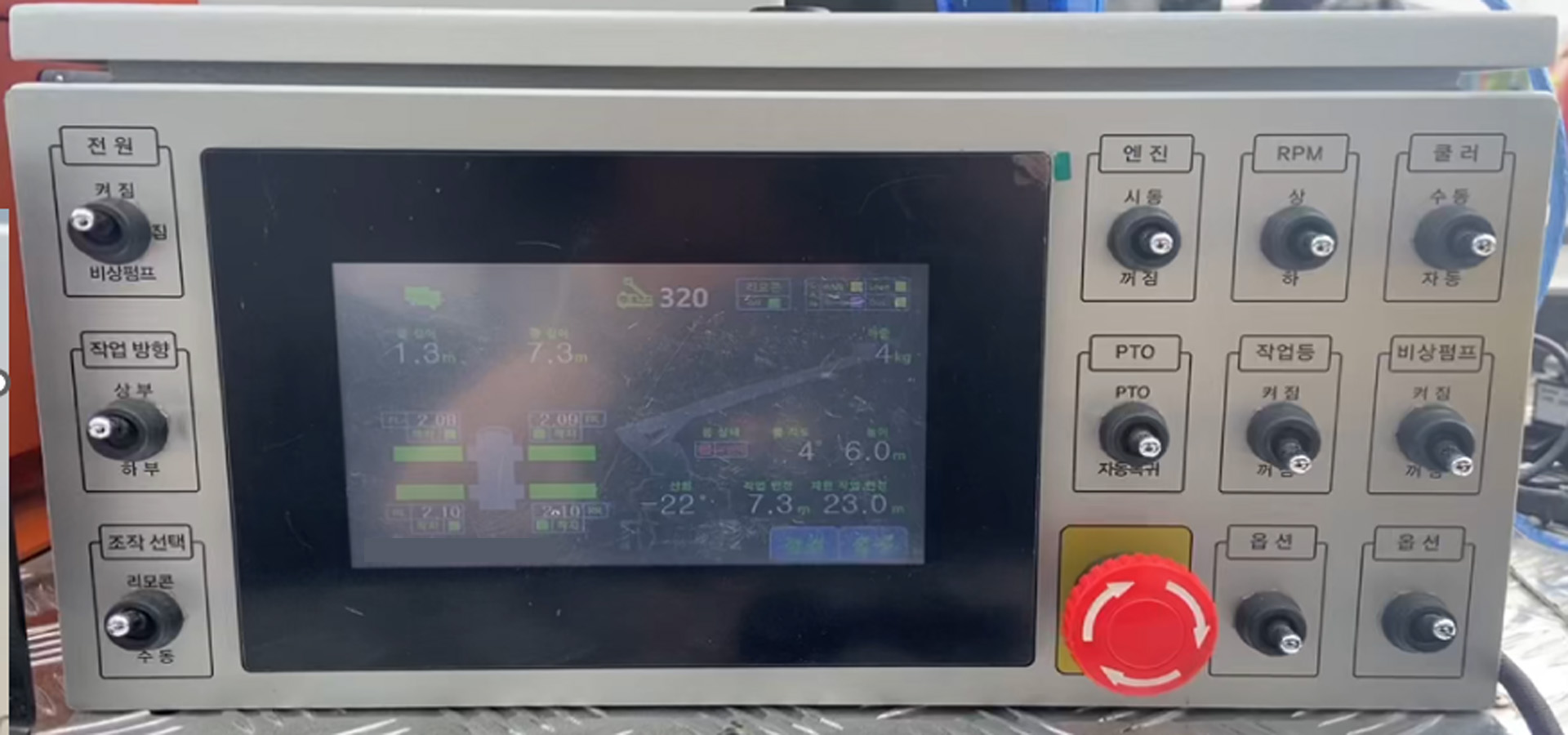

The product is designed to connect with the vehicle's ECU, enabling functions

like toggling the vehicle's ignition On/Off and activating features such as RPM

UP, DOWN, and PTO using toggle switches. Additionally, these functions can be

controlled using specific switches on the remote control.

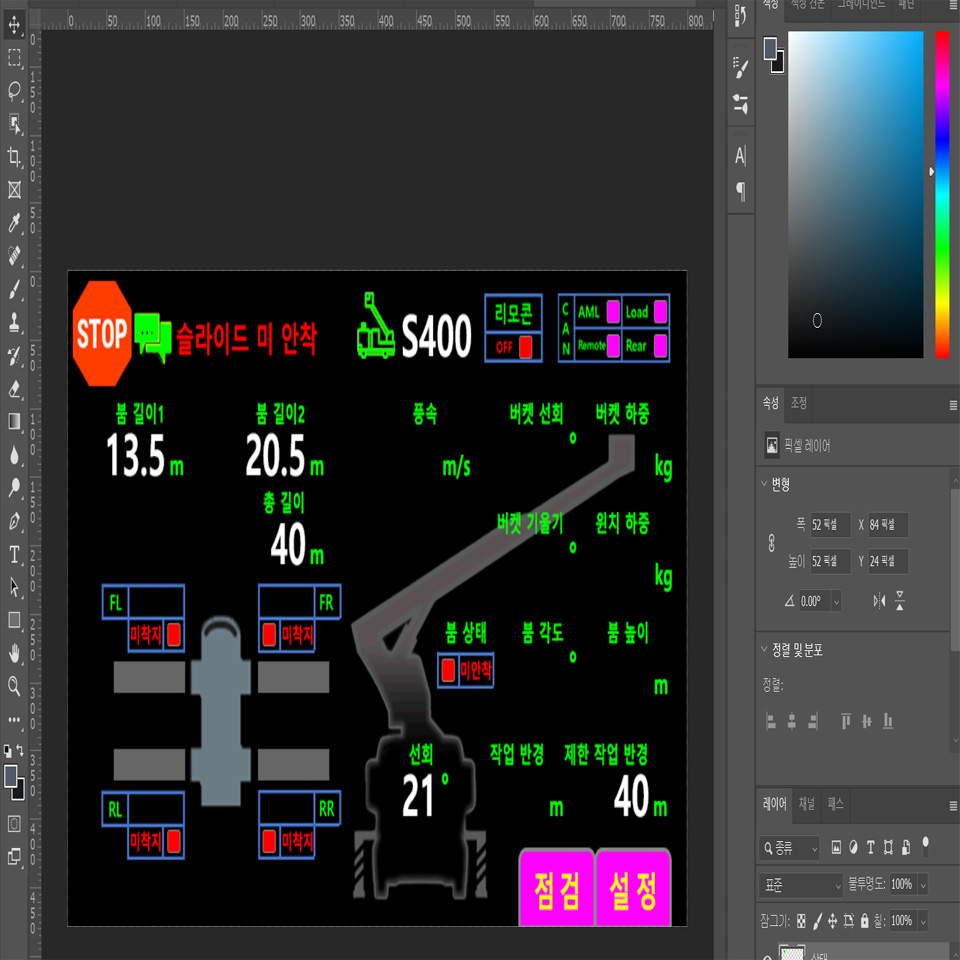

Through a touch-screen display, real-time monitoring of sensor values during

vehicle operation is possible. It also offers the capability to detect sensor

anomalies and modify sensor parameter values. These adjusted parameters are

stored in the EEPROM for future reference. Moreover, the EEPROM is programmed to

automatically retrieve stored parameters upon powering on.

Human Machine Interface

&

ECU Controller

aerial work platform truck system

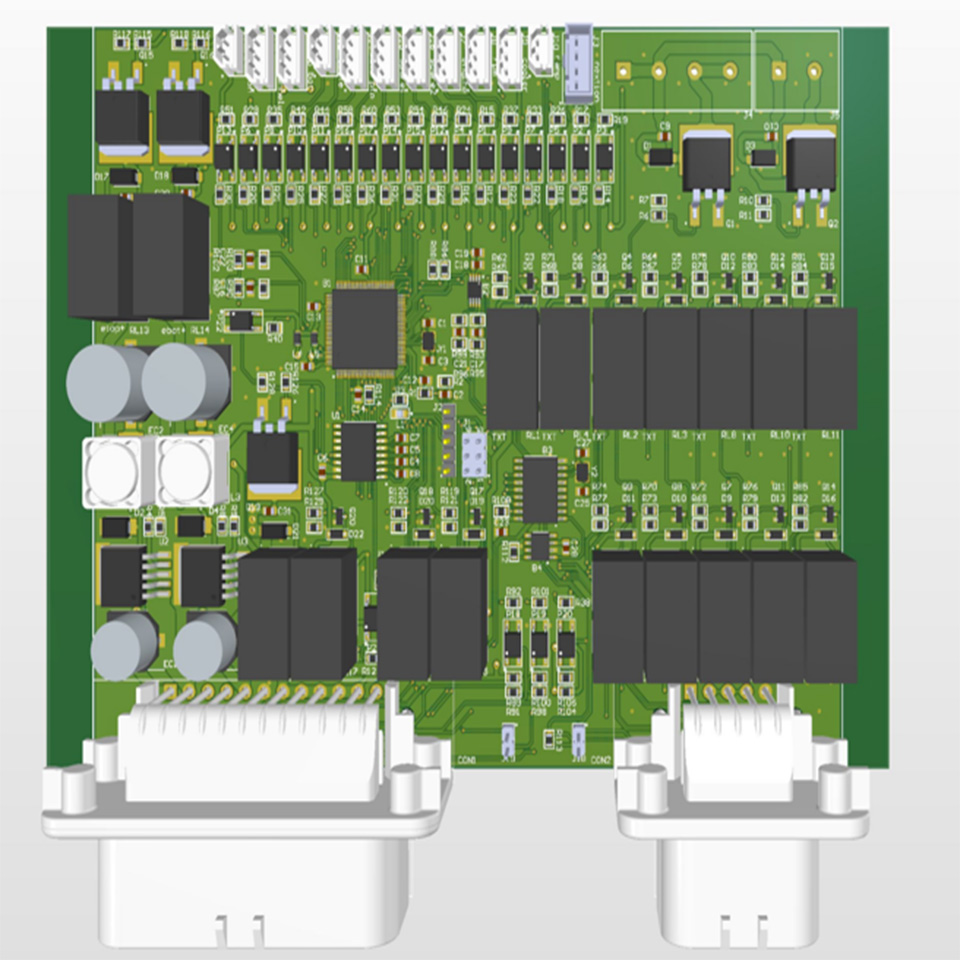

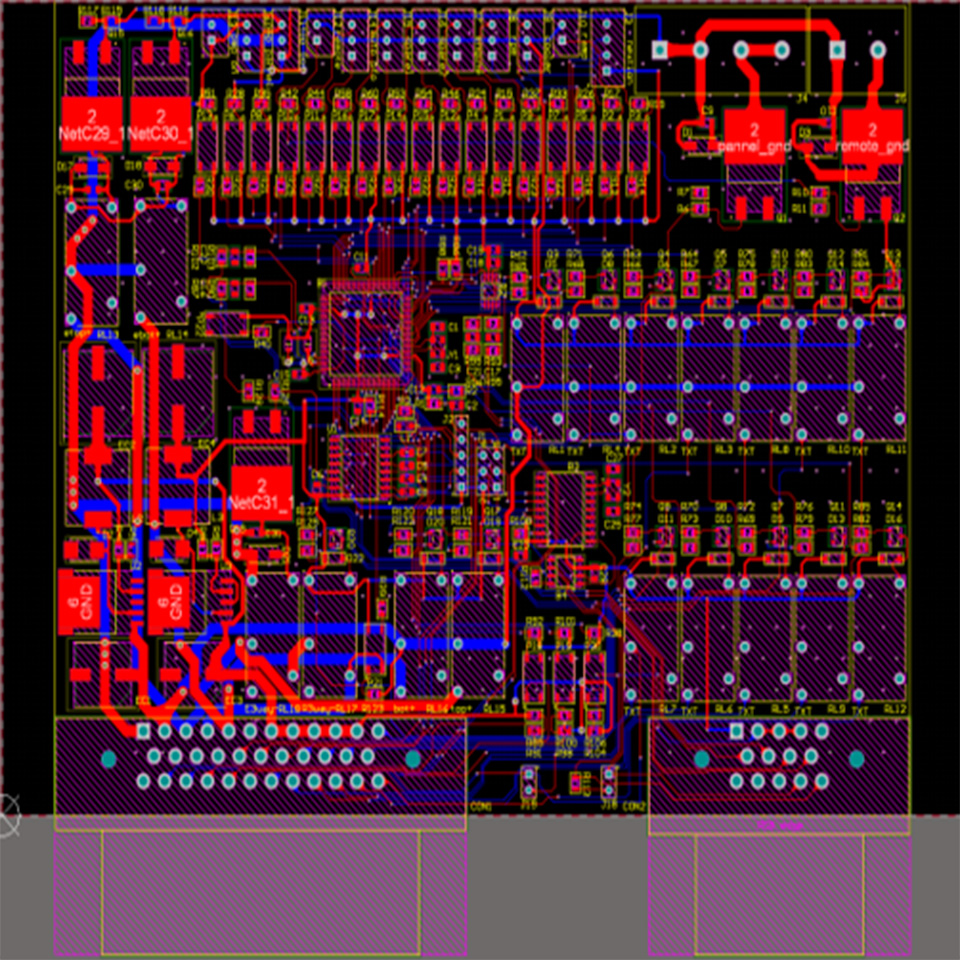

Before hardware design, I analyzed the characteristics of sensors required for

the system and the features of the system controlled through PCB connections. I

identified the necessary requirements for communication protocols and interfaces

such as CAN, I2C, GPIO, and USART, and incorporated them into the

design.

CAN : I established the CAN communication connections for data

exchange with other controllers.

I2C : Utilizing I2C communication, I integrated an ADC module

with 16-bit resolution.

GPIO : Designed considering the number of ports required for

sensors and external devices.

USART : Implemented communication with the touch-screen

display.

In addition, the system can receive input from external toggle switches via

GPIO. It reads the status of external buttons attached to the toggle switches or

wireless remote, activating relays to send signals to the vehicle's ECU. This

allows functions such as ignition control (On/Off), RPM adjustments (UP/Down),

and activation of the Power Take-Off (PTO) feature.

A touch-screen display is integrated, enabling real-time monitoring of various

sensor states and adjustment of sensor settings.

Please note that the phrasing has been adjusted for clarity and smoothness.

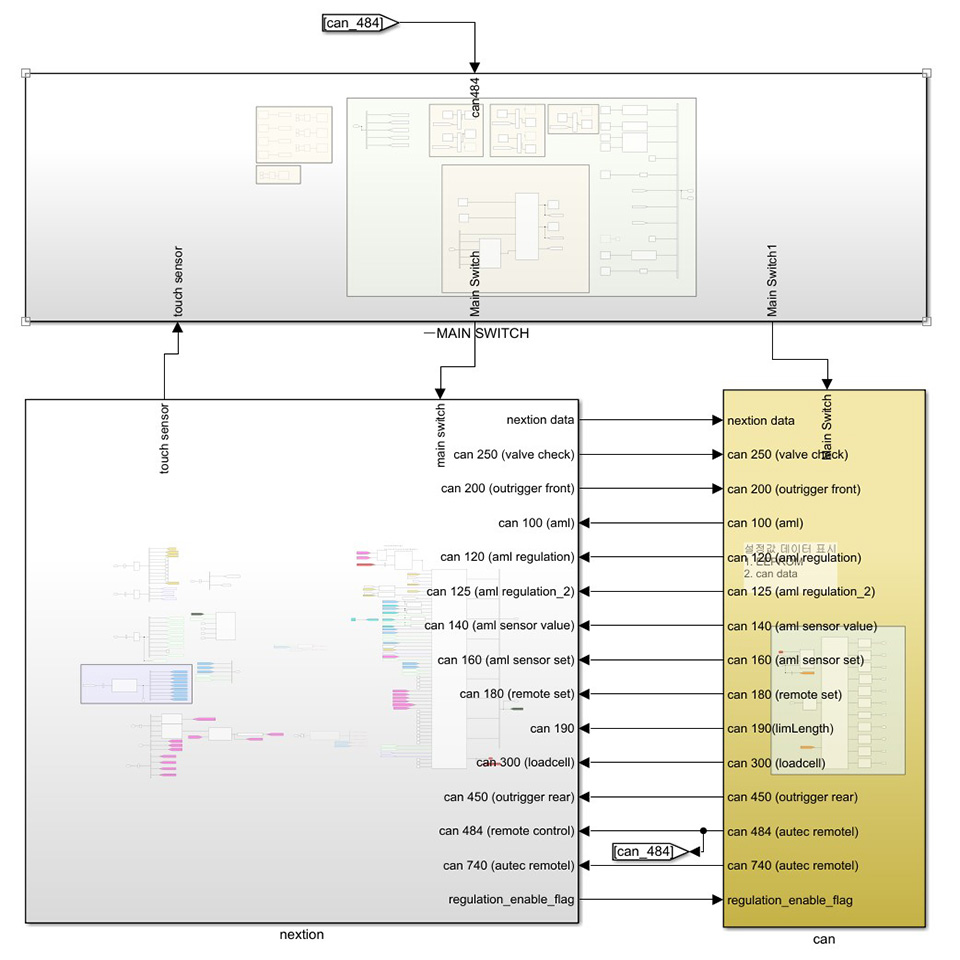

The firmware development was conducted using Simulink, and custom S-Function

blocks in C language were developed for devices such as CAN, I2C, EEPROM, and

touch-screen displays, as needed.

The programming was divided into three main parts

Switch Input and Processing : Handling operations based on

switch input states.

CAN Communication : Communication with other connected

controllers.

Display : Displaying sensor values and allowing adjustment of

settings, providing

necessary information to the user.

These techniques were programmed and tested on the MCU using MATLAB and

Simulink.

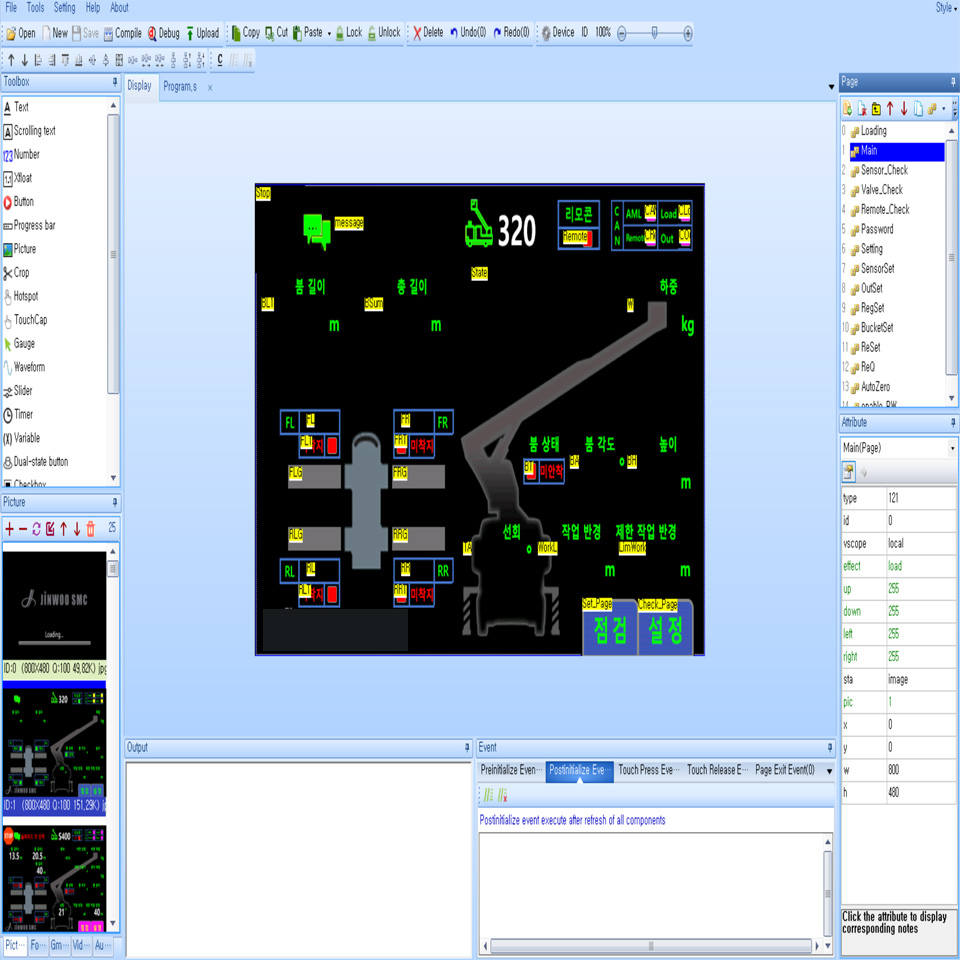

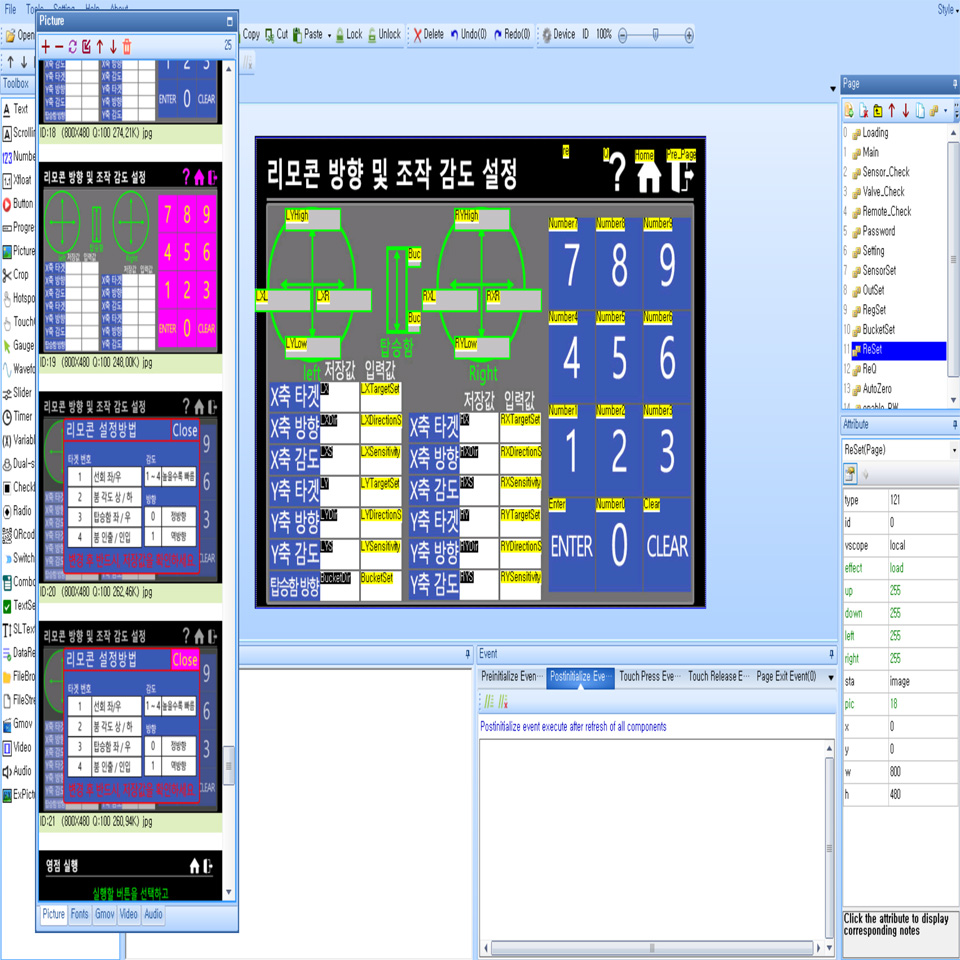

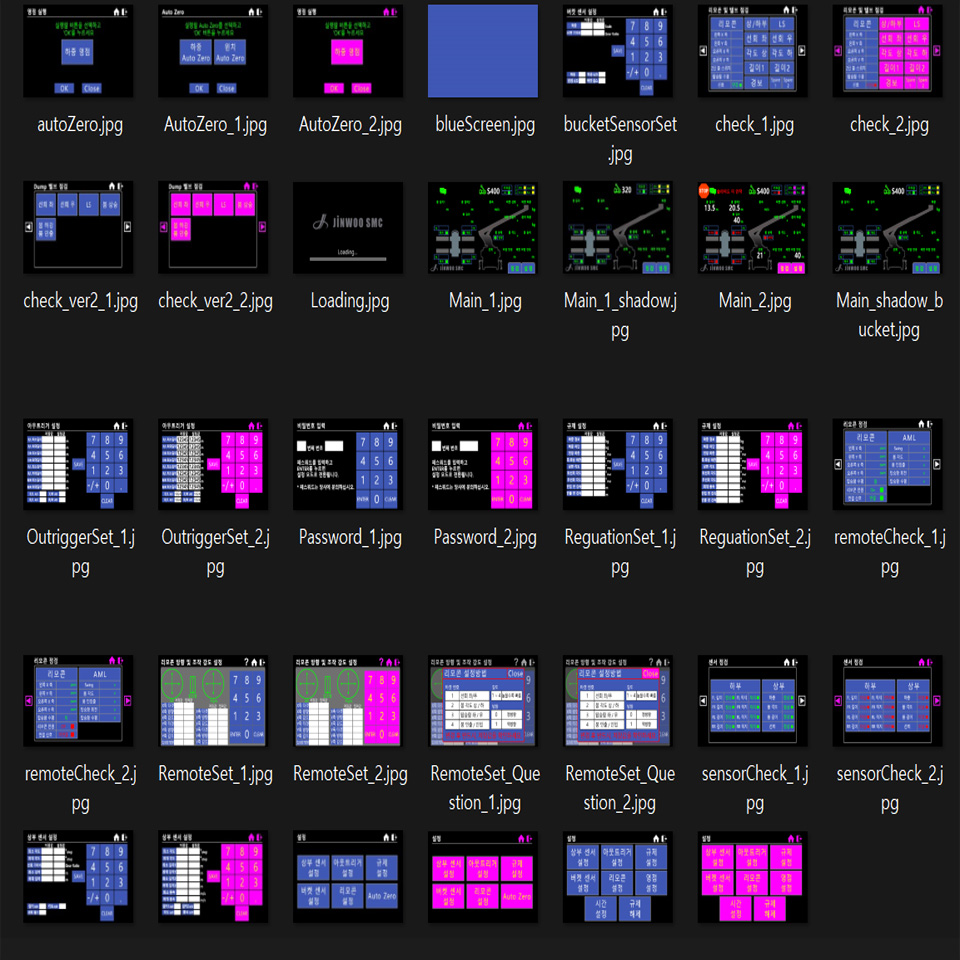

I utilized Nextion's touch-screen display. I designed various screens using

Nextion's proprietary tool and implemented the ability to input passwords and

parameter values using provided commands.

I also designed buttons and screen

components using Photoshop (allowing for potential modifications in the future).

By mastering the basic tools and commands provided by Nextion, diverse display

configurations can be created. It's a product I personally recommend.