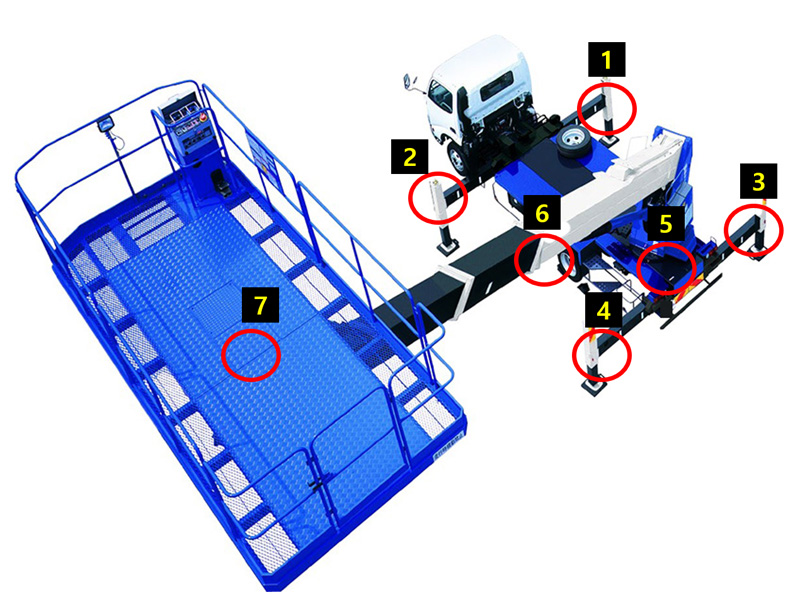

The aerial work platform is a specially designed vehicle for safe elevated

operations.

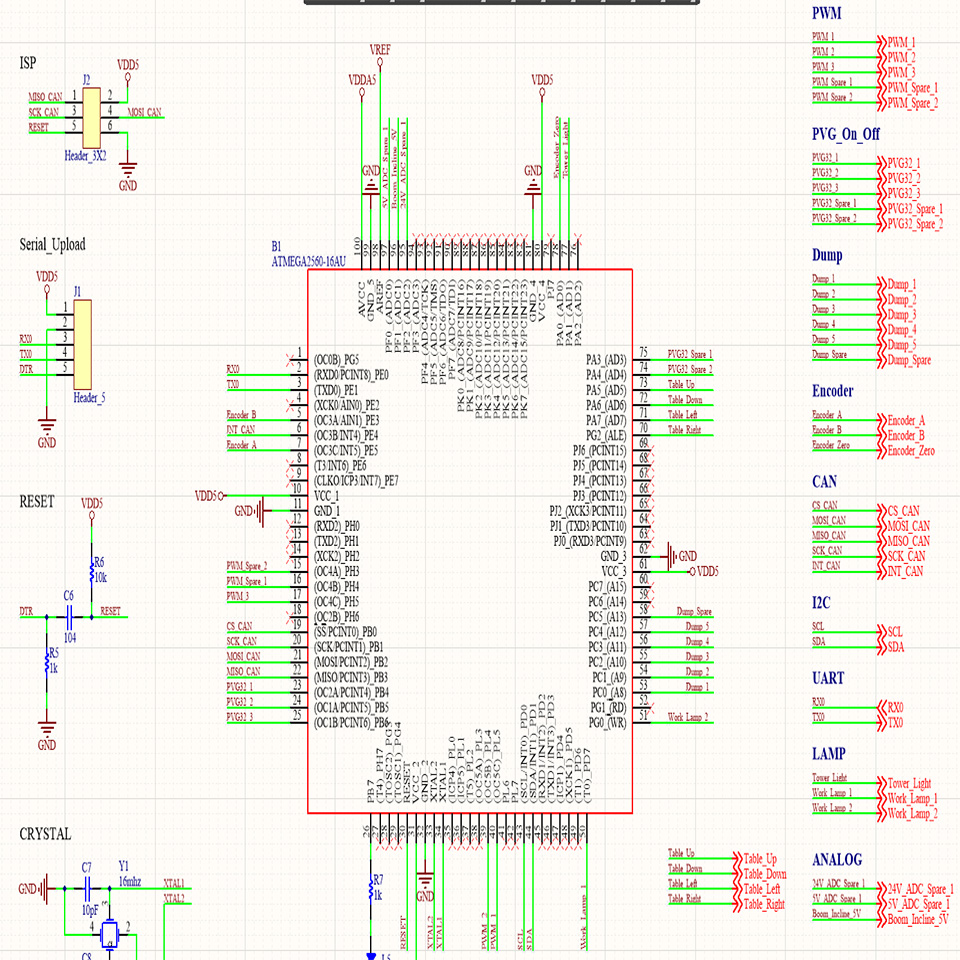

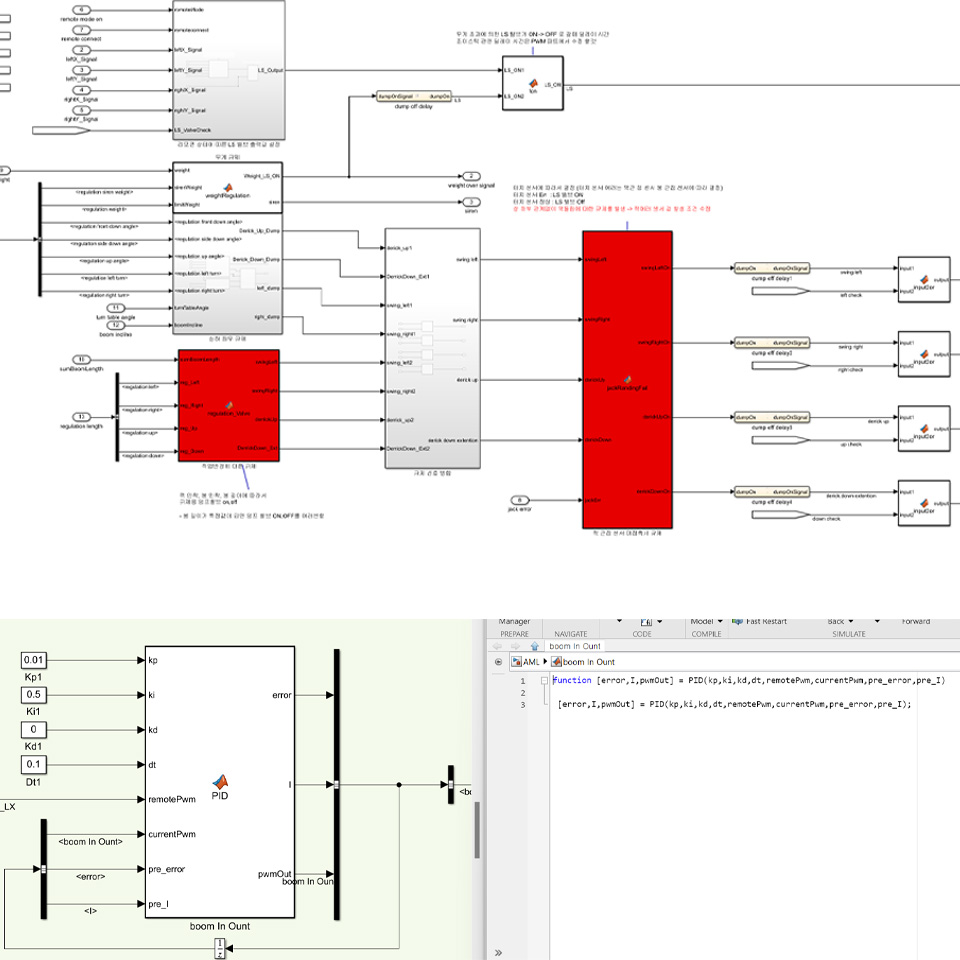

Key sensors installed to ensure the vehicle's safe functioning are as

follows:

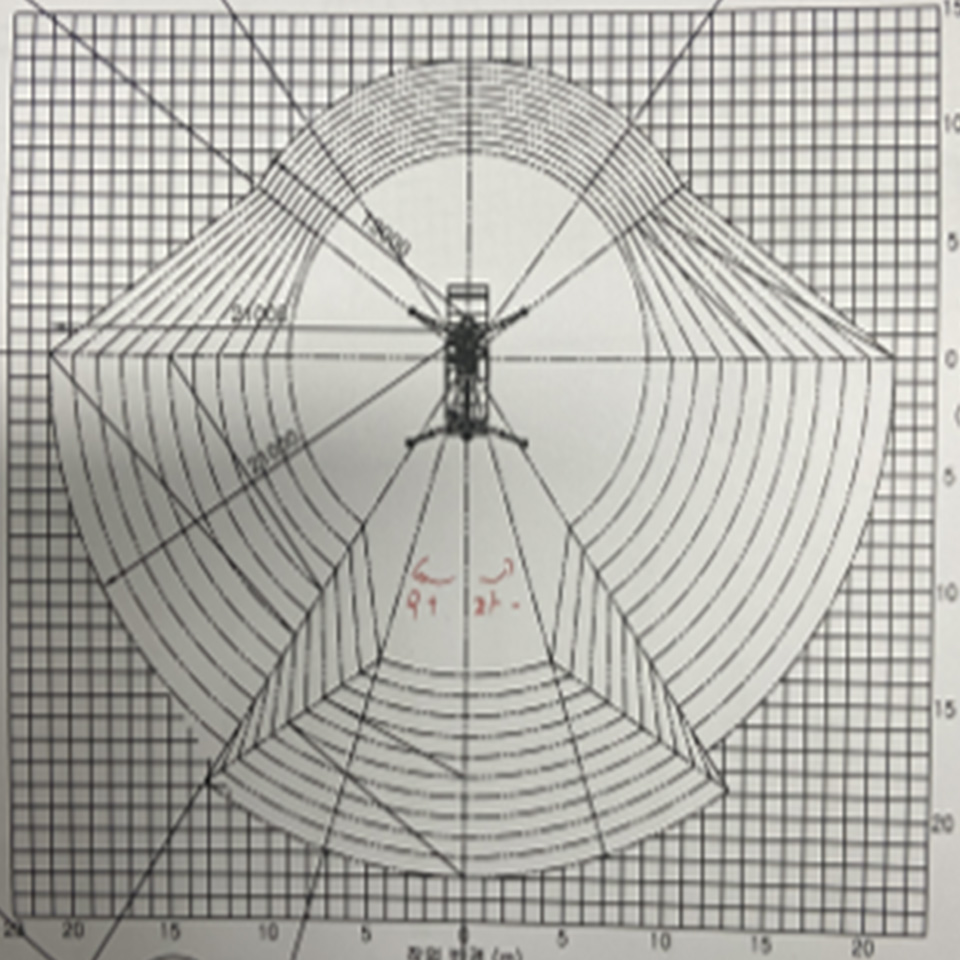

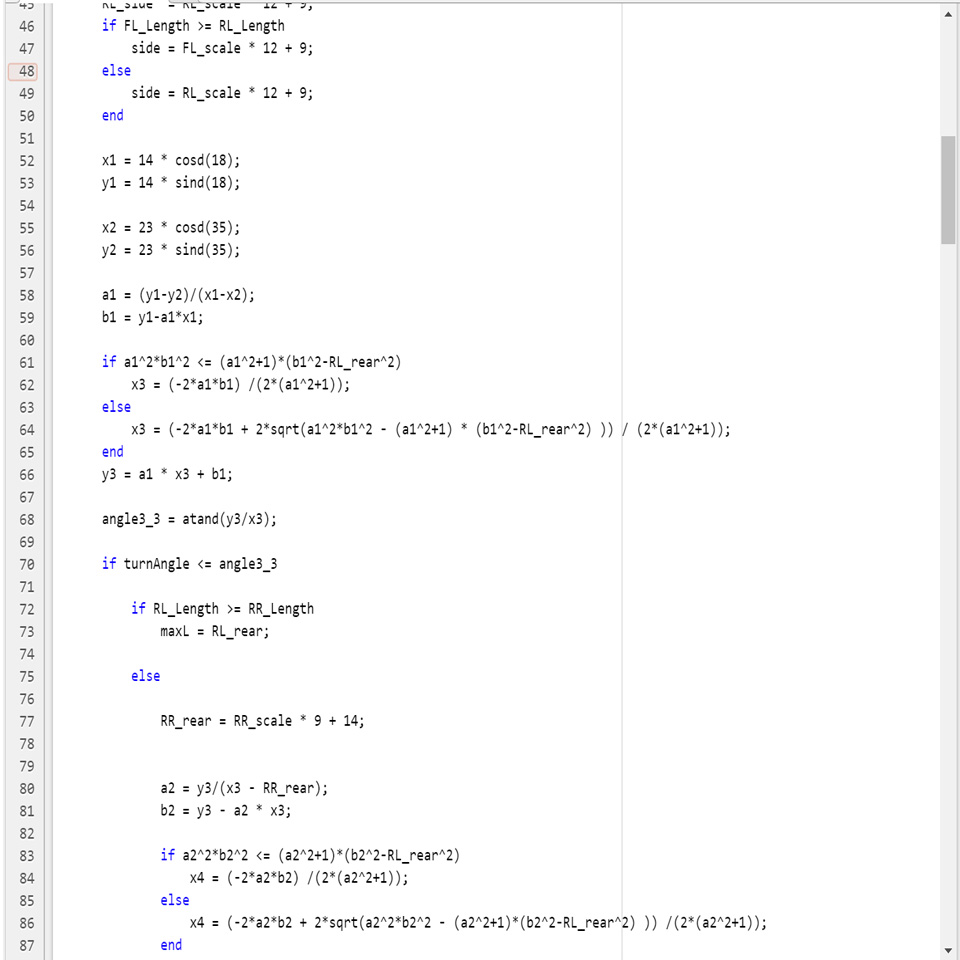

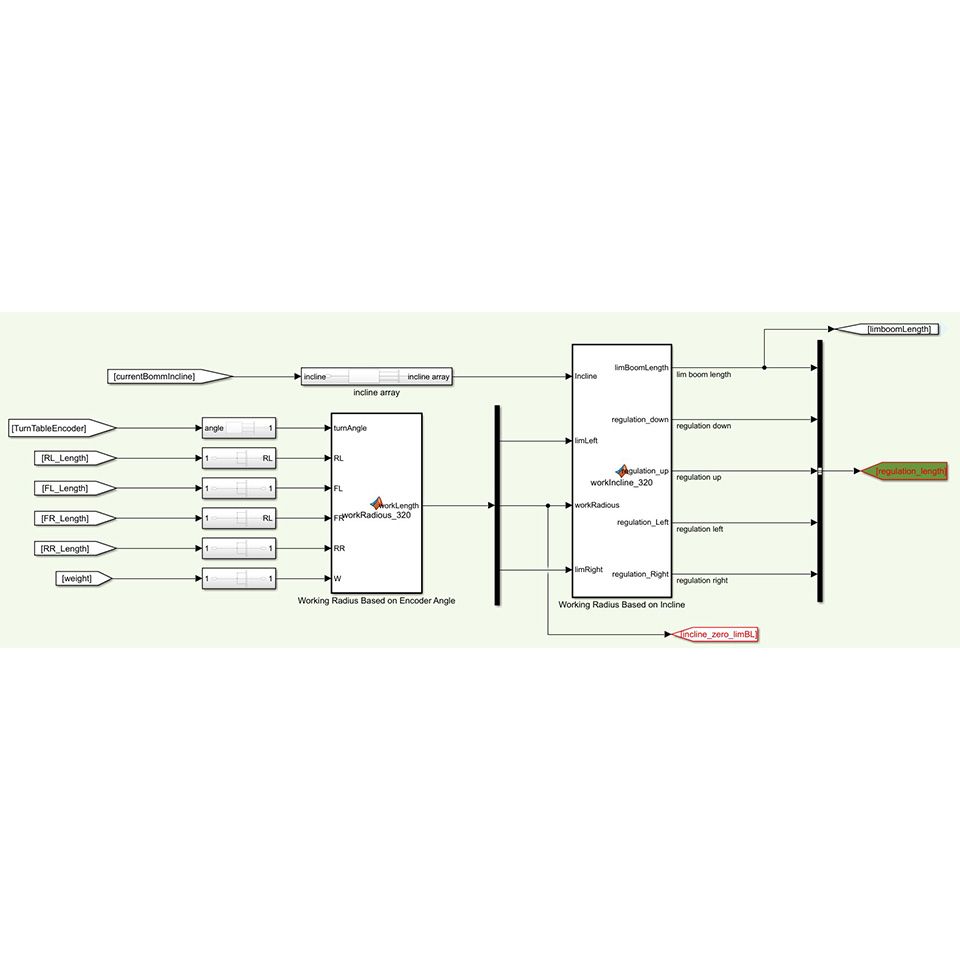

Sensors 1 to 4 consist of length sensors for stable support and proximity

sensors to verify the support status. (Greater support length allows the vehicle

to operate safely at higher heights.)

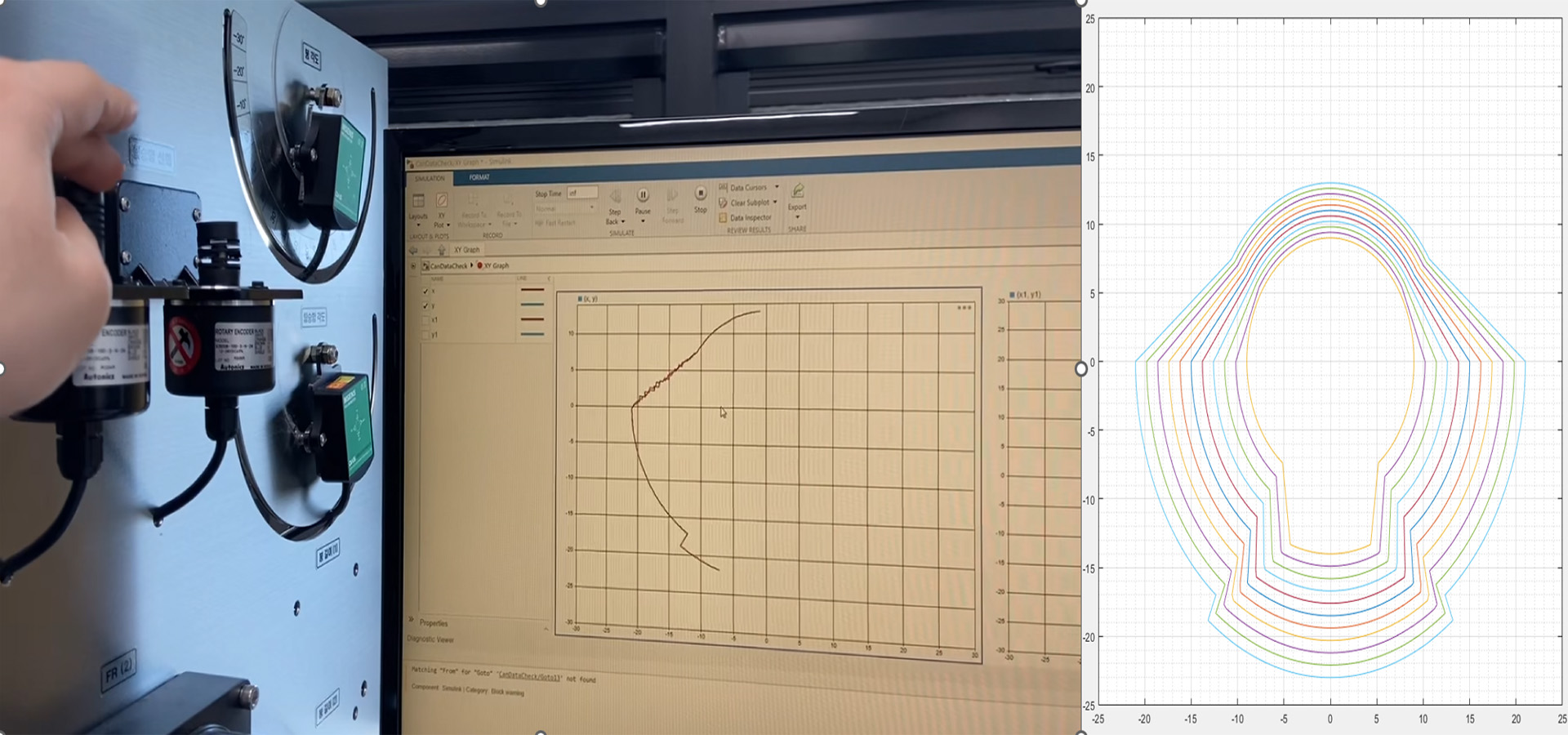

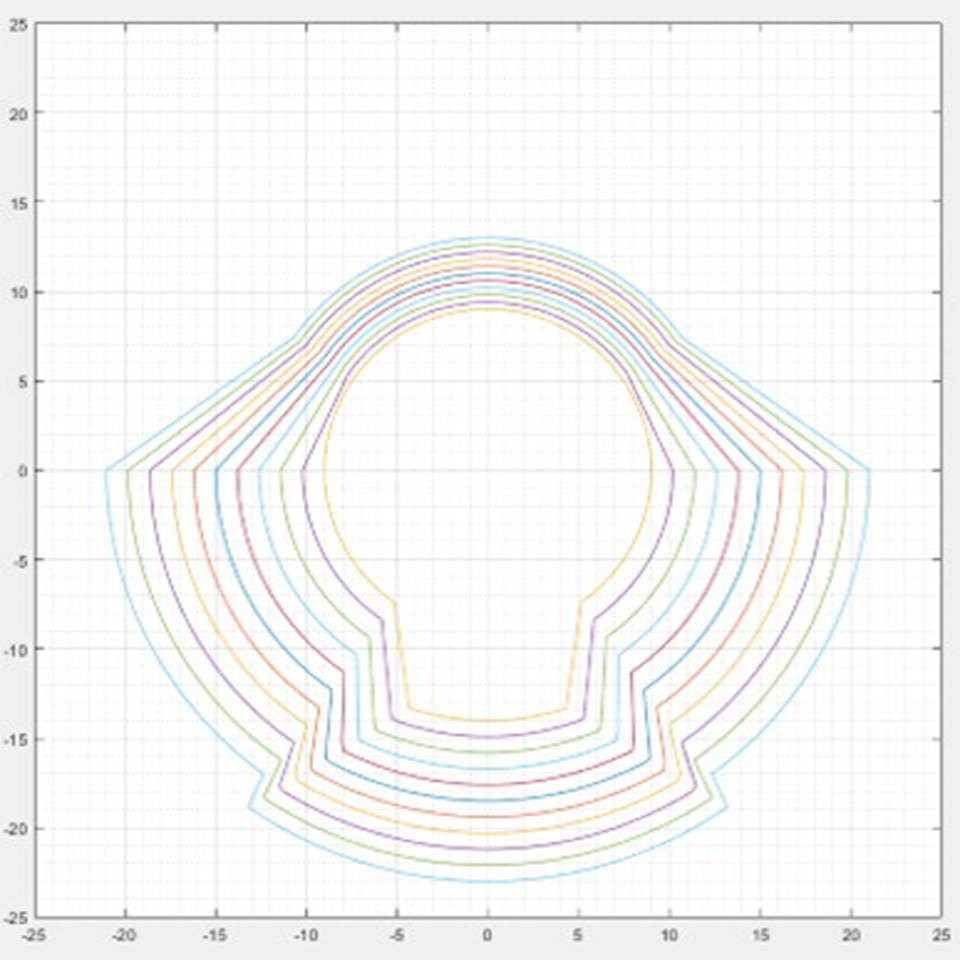

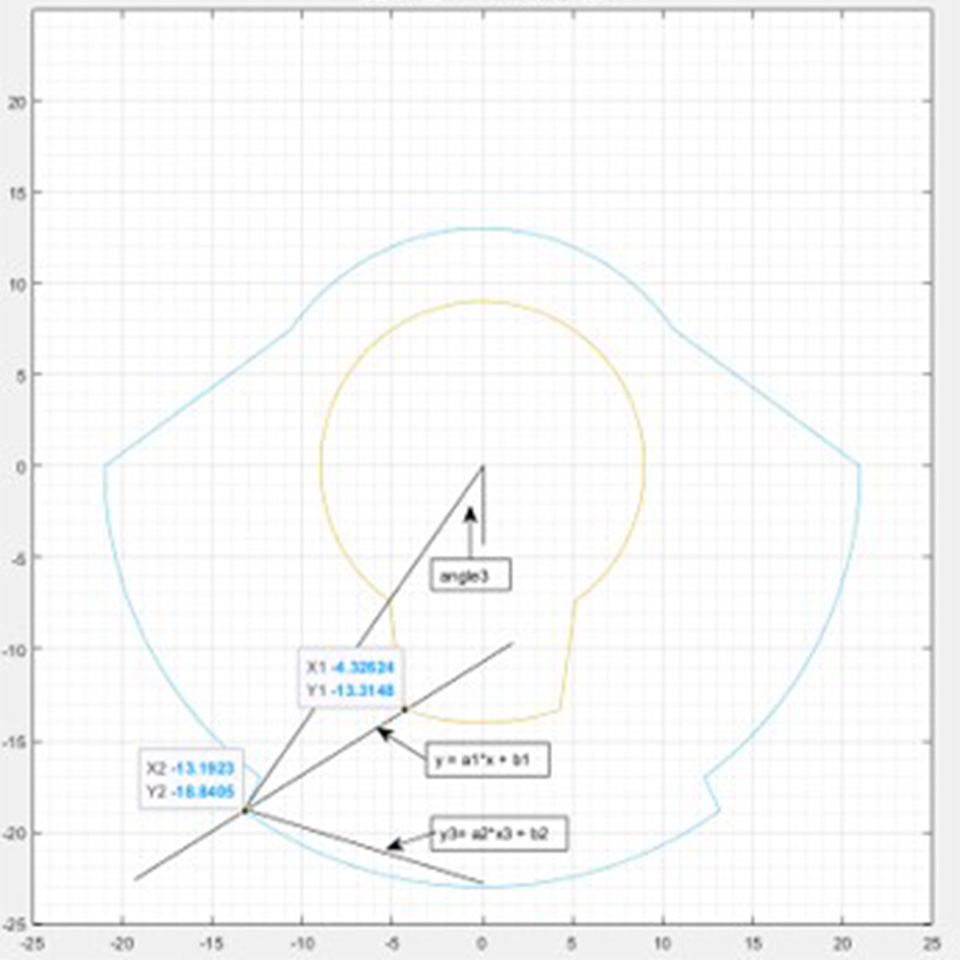

Sensor 5 is an encoder measuring the current angle of the platform, indicating

angles on the XY plane.

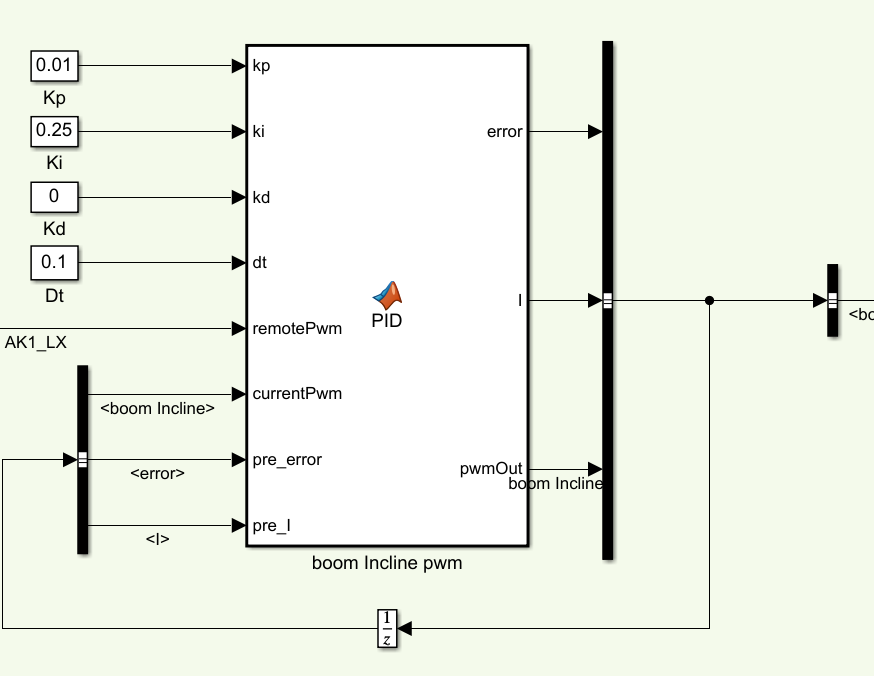

Sensor 6 includes a length sensor for determining the work length and a

gyroscope incline sensor for measuring angles on the XZ plane.

Sensor 7 incorporates a load cell to precisely measure the working weight. These

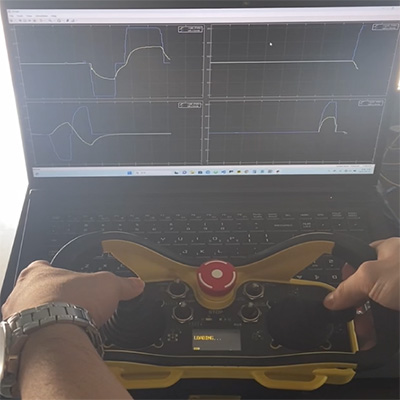

sensors, integrated with others, calculate and control the vehicle's operations

precisely, ensuring safe operations based on the vehicle's state.